The cold crimping technology is widely used in

the fields of wire harness manufacturing, aerospace, new energy vehicles, rail transportation, connector manufacturing, because of its characteristics of high

reliability, simple operation, cost saving and

no pollution. This makes manual crimping tools more widely used in related manufacturing industries. Then, do you know how to better use crimping tools to extend tool life? Here I will take M22520 series hand crimping pliers

for example to tell you a few about the use and maintenance of crimping pliers.

Tip 1 Crimping pliers are

precision tools which can not be transferred to other uses and can not operate

the tool indiscriminately. Please crimp with the appropriate force.

YJQ-W1A (M22520/2-01) Hand Crimping Pliers + SK2-2

YJQ-W7A (M22520/7-01) Hand Crimp

Pliers + 86-37 Adjustable Crimper Positioner

Tip 2 The right crimping tool should be chose to crimp the terminals and wires. When

the size of the terminal does not match that of the crimping pliers, there may

be insufficient crimp or excessive crimp. Do not insert rigid steel contacts or solid cylindrical contacts into the

crimp hole, otherwise it may cause damage to the crimping pliers.

Different Crimping Tools for

Different Terminals

Step1 Put the terminal into the crimp hole.

Step2 Insert the wire into the terminal.

Step3 Press the crimping pliers

handle properly to complete crimping.

Simple Instruction of Terminal Crimping Step(YJQ-W2D)

Tip 3 Use with suitable positioners. Install and remove the crimper positioners with the correct method. When you install or remove the positioner, the tool must be in fully open position. After crimping, remove the positioner carefully and store it securely.

Installation of Screw-adjustable Positioner

UH2-5(M22520/1-05)

Installation of TH163 Turret

Head

Tip 4 Do not twist the wire to be crimped.

Otherwise it will affect the terminal and wire crimping effect, affecting the

tension value.

Do not twist the wires to be

crimped

Wire Crimping Cross-section after twisting the wire

Tip 5 Keep the indenter tips clean

and carefully remove any remaining deposits, but do not immerse the tool

directly in

cleaning solution.

Indenters tips

of YJQ-W2A (M22520/1-01) Manual

Crimping Tool

Indenters tips of YJQ-W1A (M22520/2-01) Manual Crimping Tool

Tip 6 Crimping pliers should be

cleaned and stored in a clean, dry place to prevent dust and impurities from

entering the crimp

frame, or it will affect the performance of pliers.

The manual crimping tool YJQ-W1A(M22520/2-01)placed

in the cleaning box.

Be sure to store it carefully

and keep it safe.

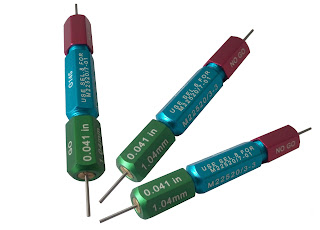

Tip 7 Crimping pliers must be regularly inspected and maintained. After being used for a certain period of time, it is necessary to check the

accuracy of the crimping pliers with a Go-NOGO gauge. As shown in the picture, operate

the tool to the fully closed position. If

the “GO” gage end can pass freely, but the NO-GO

end can not pass completely, it means the tool is still qualified.

Operation Instruction of Go-NOGO Gauge G125

(M22520/3-01)

Choose the right one to detect.

Tip 8 If the crimping pliers are broken, parts are scattered or any

abnormality is found, stop using them. Do not transform the crimping tool. Do not attempt to disassemble tool or make

repairs. Please contact the factory's technical service personnel for repair.

All these use and maintenance knowledge of crimping tools, have you

gotten it?